constructure

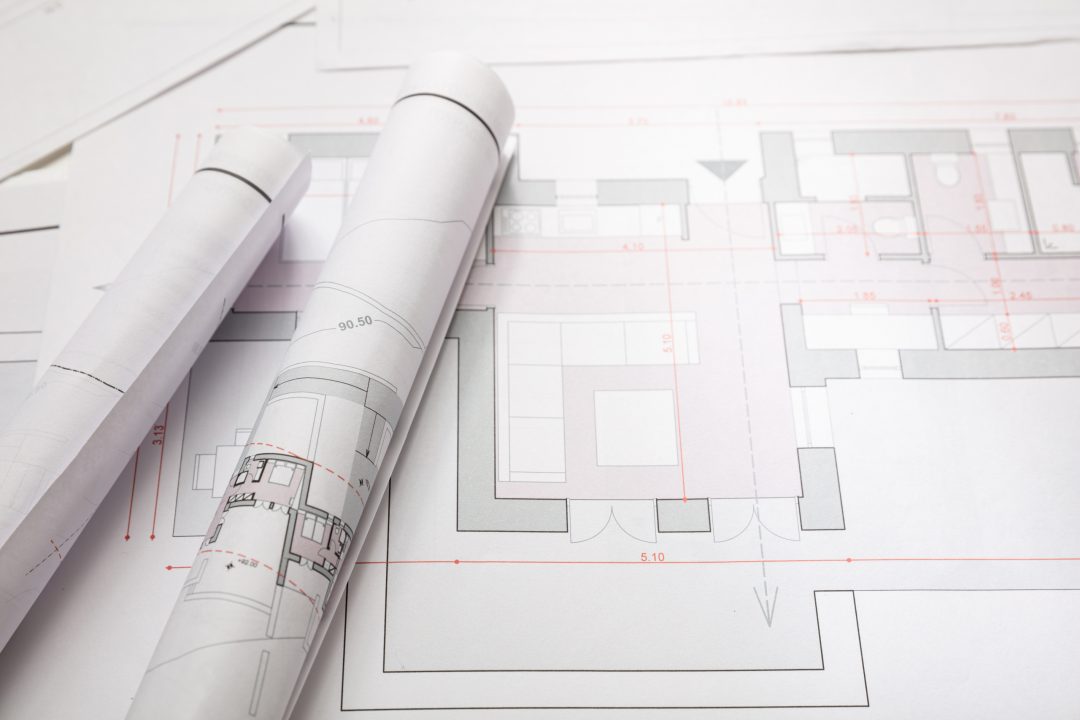

Unsere Expertise.

Constructure ist spezialisiert auf den Industrie- und Maschinenbau, die Medizin- und Energietechnik, sowie Turmbau und Hoch- und Gewerbebau. Mehr als 1.000 Projekte haben wir bis heute erfolgreich abgeschlossen. Unsere mehr als 40 Mitarbeiterinnen und Mitarbeiter sind für nationale und internationale Konzerne aktiv, für mittelständische Unternehmen, Behörden, Verwaltungen und Ministerien. Im Bereich Turmbau, Feuerfestbau und Abbruch von Industriebautechnik zählt Constructure zu den führenden Ingenieurbüros Deutschlands.

Gern präsentieren wir Ihnen unsere Referenzen und Arbeiten in einem persönlichen Gespräch. Vereinbaren Sie einen Termin mit uns. Eine erste Übersicht über unser Leistungsportfolio finden Sie hier.

Unsere Kernkompetenzen

Tätigkeiten

Unsere aktuellen Projekte